Los transformadores están fabricados según las normas IEC 60076-11 e IEEE C57.12.01 (u otras requeridas).

El núcleo esta hecho de láminas magnéticas con baja perdida y elevada permeabilidad, a 45º C y ensambladas con juntas seccionadas a intervalos con gran exactitud para así obtener el mínimo flujo residual, irrupción, bajo nivel sonoro y reducir la perdida de hierro.

Un ensamblaje preciso y de correcta sujeción garantiza una solidez uniforme y evita vibraciones, algo tan determinante para un núcleo óptimo.

Se utilizan bases y soportes de resina, altamente resistentes para sujetar las bobinas primarias y secundarias.

Las bobinas LV están hechas de aluminio con aislamiento de material clase H: esta tecnología asegura una gran resistencia a la fuerza electrodinámica.

Las bobinas entonces se impregnan con resinas polimerizadas en el horno para garantizan la protección ante la corrosión.

Las bobinas MV están hechas de bandas de aluminio, dispuestas en sub-bobinas y conectadas en series, diseñado simétricamente para así evitar el mal funcionamiento.

El aislamiento utilizado es de la clase F.

La fabricación del bobinado HV por fundición, fase fundamental en todo el proceso de producción, se obtiene con la acción combinada de vacío y temperatura.

Todo el proceso es controlado y monitorizado con un sistema de alta adquisición que permite respetar todos los parámetros necesarios para la obtención de un producto de ALTA CALIDAD.

Technical Features

STANDARD

The transformers are built in accordance with IEC 726 standards.

CORE

The core is built up of cold rollled oriented grain steel sheet with low specific losses, insulated on both sides by a thin inorganic coating (Carlyte). The sheets composing the core are cut at 45 degrees. Uniform pressing, stiffnes and solidity of the columns assure a low noise level.

MEDIUM VOLTAGE WINDINGS

The high voltage are made of electrolitic aluminium conductors (wire or foil strip depending upon power and voltage requirements). It is possible to produce copper windings. The windings are inglobed under vacuum in class F epoxidic resin. The accuracy of execution of these processes allows the obtainement of windings free from partial discharges.

LOW VOLTAGE WINDINGS

The low voltage windings are made of strip or foil (copper or aluminium conductor depending upon power and voltage requirements). Class H insulating material is used.

STANDARD ACCESSORIES

Skid under base or truck with bidirectional wheels; Lifting lugs; Earthing terminal.

OPTIONAL ACCESSORIES

Thermometer dial type whith electric contacts; Temperature monitoring unit without display; Temperature monitoring unit with display; Cubicle IP 315 or other; Forced ventilation system.

TEST

All transformers are singulary tested with routine test, according to standard IEC 726. Upon request the following type test can be carried out; temperature.

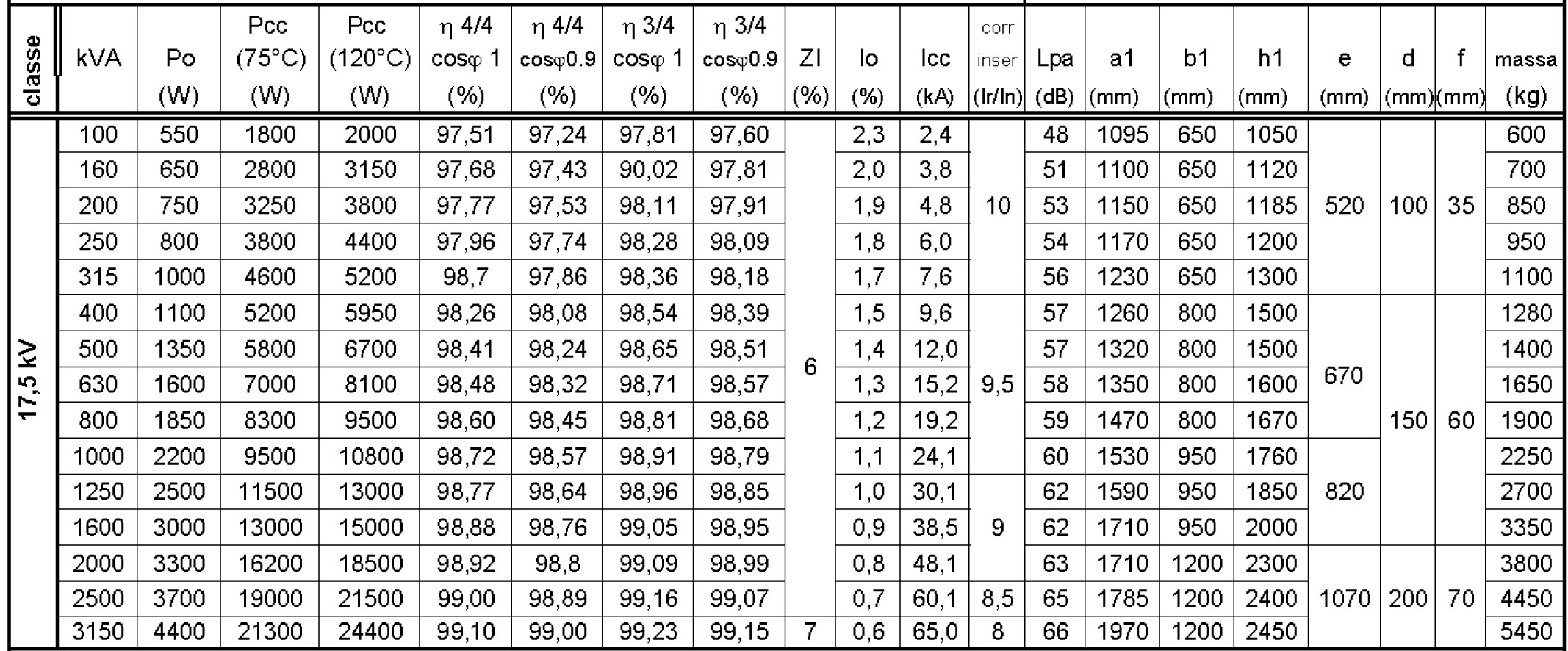

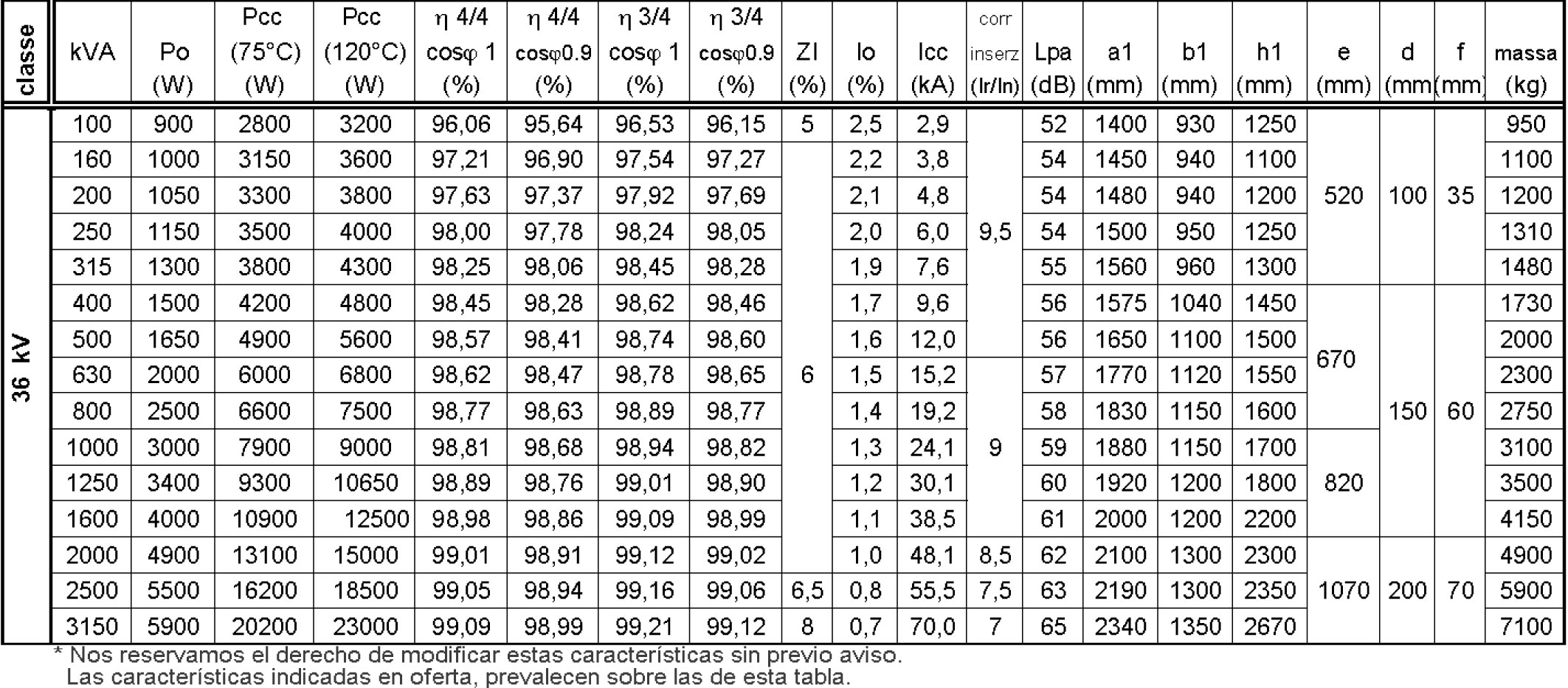

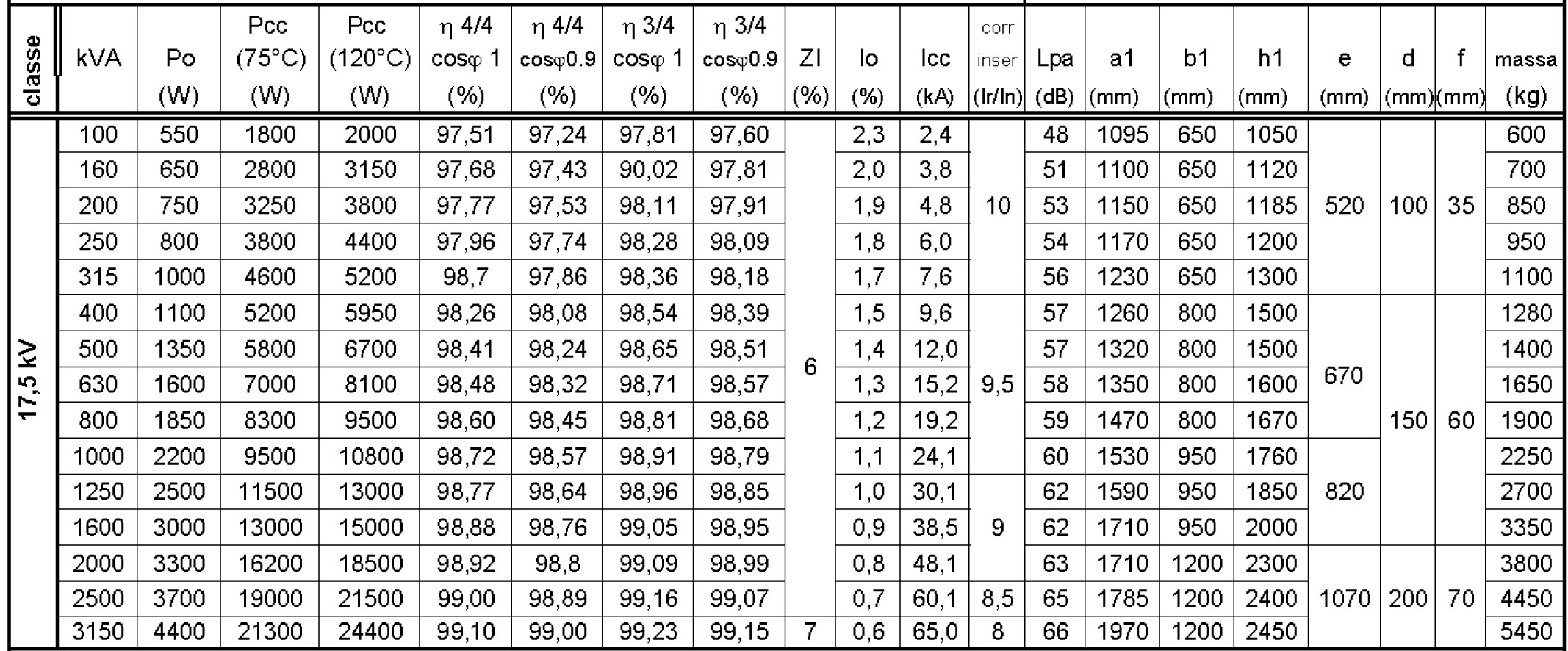

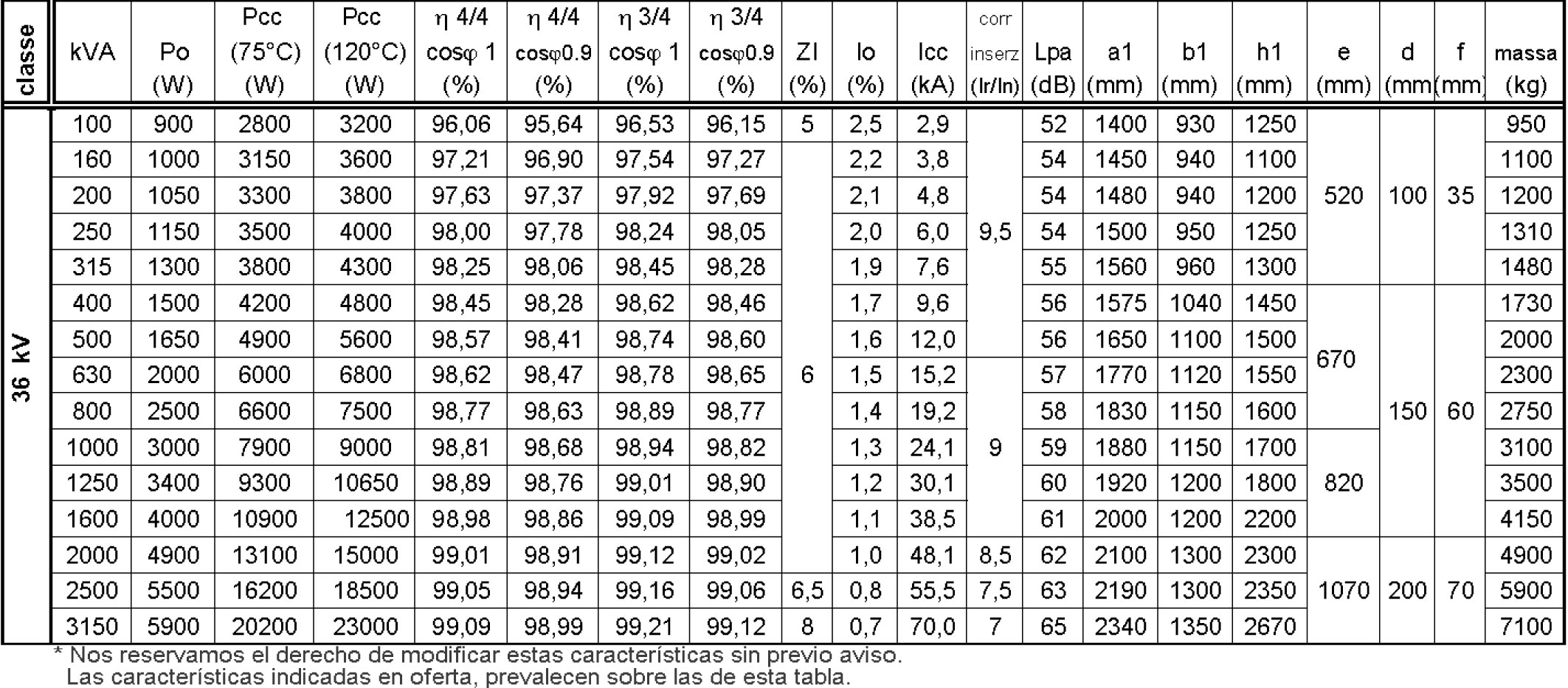

Detalles y Medidas

The transformers are manufactured according to the standards IEC 60076-11 and IEEE C57.12.01 (or other required).

The core is made of magnetic sheets with low loss and high permeability, at 45 ° C and assembled with joints cut at intervals with great accuracy to obtain the minimum residual flow, irruption, low noise level and reduce the loss of iron.

An accurate assembly and correct clamping guarantees a uniform solidity and avoids vibrations, something so decisive for an optimal core.

Resistant bases and supports are used to hold the primary and secondary coils.

The LV coils are made of aluminum with insulation of class H material: this technology ensures a great resistance to the electrodynamic force.

The coils are then impregnated with polymerized resins in the oven to ensure protection against corrosion.

MV coils are made of aluminum strips, arranged in sub-coils and connected in series, symmetrically designed to avoid malfunctioning.

The insulation used is of class F.

The manufacture of the HV winding by casting, fundamental phase in the whole production process, is obtained with the combined action of vacuum and temperature.

The whole process is controlled and monitored with a high acquisition system that allows to respect all the parameters necessary to obtain a HIGH QUALITY product.

Technical Features

STANDARD

The transformers are built in accordance with IEC 726 standards.

CORE

The core is built up of cold rollled oriented grain steel sheet with low specific losses, insulated on both sides by a thin inorganic coating (Carlyte). The sheets composing the core are cut at 45 degrees. Uniform pressing, stiffnes and solidity of the columns assure a low noise level.

MEDIUM VOLTAGE WINDINGS

The high voltage are made of electrolitic aluminium conductors (wire or foil strip depending upon power and voltage requirements). It is possible to produce copper windings. The windings are inglobed under vacuum in class F epoxidic resin. The accuracy of execution of these processes allows the obtainement of windings free from partial discharges.

LOW VOLTAGE WINDINGS

The low voltage windings are made of strip or foil (copper or aluminium conductor depending upon power and voltage requirements). Class H insulating material is used.

STANDARD ACCESSORIES

Skid under base or truck with bidirectional wheels; Lifting lugs; Earthing terminal.

OPTIONAL ACCESSORIES

Thermometer dial type whith electric contacts; Temperature monitoring unit without display; Temperature monitoring unit with display; Cubicle IP 315 or other; Forced ventilation system.

TEST

All transformers are singulary tested with routine test, according to standard IEC 726. Upon request the following type test can be carried out; temperature.

Details and Measures